Introduction

Museums are faced with the challenge of preserving artifacts for the enjoyment and education of current and future

generations. The wide variety of artifacts that museums display requires maintaining specific environmental

conditions to minimize their deterioration. Proper relative humidity (RH) control is one of the most important

environmental factors in artifact preservation.

Conservation research has shown that RH levels above 65% will promote microbial growth (primarily fungi), while

RH levels below 25% can lead to brittleness and cracking. In addition, large fluctuations in RH can lead to

dimensional changes, deformation, and mechanical stress in organic materials. Though there is still debate about the

appropriate RH requirements for museum environments, a set point of 50% (or the historic building average) with

allowable fluctuations of ±5-10% is a generally accepted guideline.

Though mechanical humidification systems for RH control are common, many museums do not use them due to

factors such as cost and the difficulty integrating them with the existing building structure and aesthetics. An

alternate method of RH control that is employed in many museums is the use of an adsorbent material in

combination with a well-sealed display case to create a micro-environment that serves to mitigate the large RH

fluctuations that the general building environment may experience.

The most commonly used adsorbent is silica gel due to its high water capacity, chemical inertness, and ability to

undergo an indefinite number of moisture cycles. This method has been prescribed in the conservation literature for

many years, most notably by Thomson (1977) who developed the idea of ‘hygrometric half-time,’ t1/2, as the time it

takes for the RH inside a case to reach the halfway point of the ambient RH. The hygrometric half time is calculated

by the following equation:

Thomson calls M the ‘specific moisture reservoir’ of the buffering material. M is defined as the mass of water (grams

of water) gained or lost per unit mass of adsorbent media (one kilogram of buffering material) for a 1% change in

RH. The M-value is essentially the slope of the buffering material’s adsorption isotherm evaluated at a specific RH,

and it describes the incremental moisture buffering capacity of a material. In order to provide effective RH control,

the adsorbent material must have a high M-value over the acceptable RH range for a given artifact. Increasing the Mfile:///

C|/Documents%20and%20Settings/Owner/My%20Documents/websites/museumClimateControls/SGelCases.htm (1 of 18)12/11/2007 11:43:48 AM

An Evaluation of Silica Gel for Humidity Control in Display Cases

value reduces the amount of adsorbent required to achieve proper control.

According to Thomson, the hygrometric half time is dependent upon two main factors: (1) the air leakage rate of the

case, N and (2) the amount of the buffering material inside the case, B. B will be referred to as the gel sizing factor; it

is the dry mass of buffering material in kg per cubic meter of case volume. By decreasing the air leakage rate or

increasing the amount of buffering material, the hygrometric half time is increased, and greater RH control inside the

case can be achieved.

Thomson states that a well-sealed case can be expected to have an air leakage rate of one air change per day. Using

Eq.1 Thomson calculates that 20 kg/m3 (1.25 lb/ft3) of silica gel with an M-value of 2 g/kg would be needed to

achieve a hygrometric half-time of 150 days for a display case having a leakage rate of 1 air change per day (ACD).

This recommendation has become the standard guideline for using silica gel as a passive RH control method inside

display cases.

Previous studies, e.g., Guinchen and Gai (1984), Schweizer (1984), Stolow (1977), have found silica gel to be an

effective method of RH control inside display cases. However, in a recent research project evaluating the

environmental conditions at the Field Museum of Natural History in Chicago a silica gel application was found to be

ineffective at controlling the RH inside a newly-constructed display case.

The case had a volume of 1.7 m3 (60 ft3) and contained Chinese wood and ivory carvings. Three cassettes, each

containing 750 grams (1.65 lbs) of Art-Sorb, were located in drawers at the bottom of the case. The Art-Sorb was

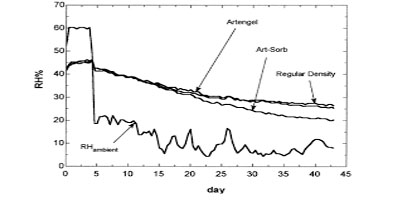

conditioned to a relative humidity of 45% prior to being placed inside the case. Figure 1 shows the relative humidity

levels measured inside and outside the case over a two-month period from February to April of 1999. The Art-Sorb

had no discernible buffering effect with the relative humidity levels inside the case being almost the same as the

ambient levels and well below the desired level of 45%.

Figure 1. Comparison of RH levels inside a display case containing Art-Sorb with ambient building levels at the

Field Museum of Natural History in Chicago, Illinois.

file:///C|/Documents%20and%20Settings/Owner/My%20Documents/websites/museumClimateControls/SGelCases.htm (2 of 18)12/11/2007 11:43:48 AM

An Evaluation of Silica Gel for Humidity Control in Display Cases

This experience became a motivating factor for the present study. The goal of this study was to evaluate the

effectiveness of silica gel for use in controlling RH levels inside display cases. The study consisted of the following

parts:

m experimentally determine the adsorption and desorption isotherms of the three silica gels

m develop a mathematical model of the solid adsorbent media for passive RH control in a display case

application

m experimentally validate the model

m use computer simulations to evaluate the effect of varying building and case conditions on silica gel

performance.

Three silica gels were evaluated in the study. They were generic regular density silica gel, which is available from

many chemical supply companies, and two specialty gels marketed specifically for museum conservation

applications: Artengel and Art-Sorb.

Experimental Measurement of Adsorption and Desorption Isotherms

The adsorption and desorption isotherms describe the equilibrium moisture concentration (EMC) of a material at

different RH levels.

The isotherms of the three gels were measured experimentally by allowing samples to come into equilibrium at

different RH levels inside a constructed humidity chamber and measuring their weight gain in water. Equilibrium

was attained when the measured weight of the gel samples did not change over time.

Table 1. Equilibrium relative humidity values at

25°C. for salt solutions used in isotherm

experiments from Greenspan (1977).

Salt Equilibrium RH % at 25

C

Lithium Chloride 11

Magnesium

Chloride

33

Potassium

Carbonate

43

Sodium Bromide 58

Sodium Chloride 75

The isotherms were measured three times to verify their accuracy. Weight measurements were made with a Sartorius

L420 S top-loading laboratory scale (accuracy ±0.0005 g) which was located in the humidity chamber. Different RH

levels were achieved using the saturated salt solutions listed in Table 1, the work of Greenspan (1977).

file:///C|/Documents%20and%20Settings/Owner/My%20Documents/websites/museumClimateControls/SGelCases.htm (3 of 18)12/11/2007 11:43:48 AM

An Evaluation of Silica Gel for Humidity Control in Display Cases

The RH inside the chamber was measured using a Hobo H8 Pro Series Temp/RH data-logging sensor with a stated

manufacturer’s accuracy of ±3% RH and ±0.3°C. An isotherm set was also measured using a high accuracy General

Eastern Hygro M-1 dew point hygrometer (accuracy ±0.2°C).

Experimental Isotherm Data

Table 2 shows the experimental adsorption and desorption isotherm data for the three gels. All the data were

obtained at temperatures between 23-25°C. The EMC of each gel is expressed as a percentage of the gel’s dry

weight, so an EMC of 20% means that the gel would be able to hold an amount of water equal to 20% of its dry

weight.

Adsorption Isotherm

RH % Equilibrium Moisture Concentration(%)

Regular

Density

Artengel Art-Sorb

11 9 8 8

11 9 9 9

11 7 7 8

33 19 17 14

33 20 19 16

33 19 18 15

44 24 23 18

44 25 24 19

44 26 25 19

60 31 35 25

60 32 35 27

63 32 37 31

74 34 43 53

74 34 43 54

100 37 48 95

file:///C|/Documents%20and%20Settings/Owner/My%20Documents/websites/museumClimateControls/SGelCases.htm (4 of 18)12/11/2007 11:43:48 AM

An Evaluation of Silica Gel for Humidity Control in Display Cases

100 37 48 100

100 37 47 109

Desorption Isotherm

RH % Equilibrium Moisture Concentration (%)

Regular

Density

Artengel Art-Sorb

11 9 9 10

11 8 8 8

11 9 8 9

34 24 20 15

34 24 20 17

34 25 21 17

46 31 33 21

46 31 34 20

46 31 35 22

62 33 41 31

62 33 41 34

65 33 41 39

74 34 43 66

74 34 44 66

The experimental isotherm data were fitted to the Dubinin-Astakhov (D-A) (1977) equation using a non-linear least

squares method. The D-A equation expresses the equilibrium moisture concentration of the gel as a function of the

adsorption potential, A defined as:

The Dubinin-Astakhov equation is given by:

EMC%=q x 100 (Eq. 4)

where q0, q1, E0, E1, n1, and n2 are equation parameters.

file:///C|/Documents%20and%20Settings/Owner/My%20Documents/websites/museumClimateControls/SGelCases.htm (5 of 18)12/11/2007 11:43:48 AM

An Evaluation of Silica Gel for Humidity Control in Display Cases

Figures 2-4 compare the isotherm’s curve fits from the Dubinin-Astakhov equation with the experimental data for

regular density silica gel, Artengel, and Art-Sorb, respectively. All three gels show some hysteresis with the

desorption isotherm lying above the adsorption isotherm. Art-Sorb has the least amount of hysteresis with most of it

occurring above 60%. Regular density silica gel’s hysteresis occurs below 60%, while Artengel’s occurs in the 30-

70% range.

Figure 2. Regular density silica gel.

file:///C|/Documents%20and%20Settings/Owner/My%20Documents/websites/museumClimateControls/SGelCases.htm (6 of 18)12/11/2007 11:43:48 AM

An Evaluation of Silica Gel for Humidity Control in Display Cases

Figure 3. Artengel

file:///C|/Documents%20and%20Settings/Owner/My%20Documents/websites/museumClimateControls/SGelCases.htm (7 of 18)12/11/2007 11:43:48 AM

An Evaluation of Silica Gel for Humidity Control in Display Cases

Figure 4. Art-Sorb

Gel Comparison

In comparing the gel isotherms, it is best to focus on the 30-60% RH range since that is the desirable range for

museum environments. Figure 5 shows the EMC of the three gels in the 30-60% RH range. In this range, Art-Sorb

has a lower moisture capacity than Artengel and regular density silica gel, which have similar capacities.

file:///C|/Documents%20and%20Settings/Owner/My%20Documents/websites/museumClimateControls/SGelCases.htm (8 of 18)12/11/2007 11:43:48 AM

An Evaluation of Silica Gel for Humidity Control in Display Cases

Figure 5. Equilibrium moisture capacity of three gels in the relative humidity range of 30-60%.

In evaluating the buffering performance of the three gels, it is more appropriate to use the change in moisture

capacity over a given RH range, represented by the M-value, rather than the specific moisture capacity at a specific

RH as shown on the isotherm plots. Over a given RH range, a gel with a linear isotherm will have a constant Mvalue

and thus a constant performance, while a gel with a non-linear isotherm will have a varying M-value and thus

its performance will vary with RH. Since the M-value is essentially the slope of the isotherm at a given RH, it can be

calculated for each of the three gels by taking the derivative of the D-A equation. Figure 6 compares the M-values

for the three gels based upon their adsorption isotherms over the 30-60% RH range. Artengel has a fairly constant Mvalue

of 7 g/kg. The M-value for Art-Sorb increases with RH from 3 to 10 g/kg, while regular density’s M-value

decreases with RH from 6 to 3 g/kg.

file:///C|/Documents%20and%20Settings/Owner/My%20Documents/websites/museumClimateControls/SGelCases.htm (9 of 18)12/11/2007 11:43:48 AM

An Evaluation of Silica Gel for Humidity Control in Display Cases

Figure 6. Comparison of M-values for the three adsorbants in the 30-60% RH range.

Based upon these results, Artengel would be expected to have a consistent performance over the 30-60% RH range.

Art-Sorb’s performance would be better in the higher RH range, while regular density’s performance would be better

in the lower RH range.

Using eq. 1, Thomson’s original calculations were revisited using the present results to determine the amount of each

gel required to achieve a case half-time of 150 days with a case leakage rate of 1 ACD. Table 3 lists these results

along with the calculated cost of each gel per unit of case volume.

Table 3. Comparison of calculated gel sizing factors and costs

using Thompson’s equation to achieve a case half-time of 150

days with a case leakage rate of 1 ACD.

Gel Gel Mvalue

@

45%

RH

Gel

Sizing

Factor

(kg gel/

m3 of

case)

Gel

Cost ($/

kg of

gel)

Gel

Cost ($/

m3 of

case)

Regular density 4.5 7 16 110

ArtengelTM 7 4.6 22 100

file:///C|/Documents%20and%20Settings/Owner/My%20Documents/websites/museumClimateControls/SGelCases.htm (10 of 18)12/11/2007 11:43:48 AM

An Evaluation of Silica Gel for Humidity Control in Display Cases

Art-Sorb TM

(study data)

3 10 40 400

Art-Sorb TM

(company data)

4.7 6.5 40 260

The results presented in Table 3 are based upon each gel’s M-value at 45% RH (the middle of the 30-60% range). Art-

Sorb’s M-value was calculated using both the measured isotherm data and the data listed in the company’s literature.

Regular density silica gel costs are calculated from the stated bulk price from a common manufacturer. The costs for

Artengel and Art-Sorb are based upon each company’s stated price for bead type media.

Since Artengel has the highest M-value of 7 g/kg, it has the smallest sizing factor of 5 kg/m3. Art-Sorb and regular

density silica gel have about the same M-value around 5g/kg and thus have similar sizing factors of around 7 kg/m3.

On a cost basis, Artengel and regular density have nearly the same unit cost (i.e. cost per unit of case volume), while

Art-Sorb has more than double the cost of regular density silica gel.

Case Model

In order to evaluate the long-term performance of the three gels under varying conditions, a computer model was

developed. The following assumptions were used in the modeling of silica gel behavior inside of a display case:

m Case material and artifact have negligible water buffering capacity i.e. the buffering material preferentially

adsorbs and desorbs moisture.

m No spatial variation of RH inside the display case.

m Dry bulb temperature inside the case microenvironment is the same as the building macroenvironment.

m Temperature of the buffering media is the same as the dry bulb temperature in the case microenvironment.

The two water exchange processes included in the model are: (1) the exchange of water vapor between the case

microenvironment and ambient building macroenvironment air due to infiltration and (2) the exchange of water

vapor between the gel and case air. The rate of water exchange due to infiltration is expressed by:

Because the movement of air inside a well-sealed display case is dominated by free convection, intra-particle

resistance is assumed to be negligible and the transport of water vapor from the bulk case air to the gel surface is

assumed to be the dominant resistance to mass transfer. From the work of Kafui (1994), the rate of mass transfer

from the case air to the gel surface can be described by a lumped external mass transfer coefficient, Kgel, with the

change in water concentration of the adsorbent media with time being expressed by:

A water balance that includes these two water exchange processes can be written

file:///C|/Documents%20and%20Settings/Owner/My%20Documents/websites/museumClimateControls/SGelCases.htm (11 of 18)12/11/2007 11:43:48 AM

An Evaluation of Silica Gel for Humidity Control in Display Cases

where mH2O is the mass of water in the case at time t and mH2O,0 is the initial mass of water. Knowing mH2O, the

relative humidity can be calculated as a function of time using psychrometric relations.

Model Validation

The validity of the model was determined by comparing model predictions with the results of a long-term experiment

that measured the RH inside three moisture-impervious containers, each with a volume of 3.79 liters.

Each container held a 10-gram sample of one of the three gels which was initially conditioned to an RH of 43%. A

30-mm hole located in the top of each container allowed each container to have a similar leakage rate. The RH inside

the containers and the ambient room value was measured using a Hobo H8 Pro Series Temp/RH sensor. The longterm

experiments involved monitoring the RH for a period spanning 42 days.

Figure 7 compares the model predictions with the long-term experimental data for regular density silica gel. Figure 8

compares the performance of the three gels for the long-term experiment. Regular density silica gel and Artengel

perform almost identically with a final RH of 26%, while Art-Sorb is less effective with a final RH of 20%. For all

three gels, the model prediction is within the ±3% accuracy of the measured data.

Figure 7. Comparison of model prediction with experiment data for regular density silica gel.

file:///C|/Documents%20and%20Settings/Owner/My%20Documents/websites/museumClimateControls/SGelCases.htm (12 of 18)12/11/2007 11:43:48 AM

An Evaluation of Silica Gel for Humidity Control in Display Cases

Figure 8. Comparison of gel performance for long-term experiment.

Simulation of Silica Gel Performance

Using the model, simulations were run to evaluate the performance of the three gels inside display cases under

varying building and case conditions. Three different ambient building RH profiles representing a dry, humid, and

moderate building environments were used to drive the model. A dry building environment was simulated by using

RH measurements taken over a one-year period at the Field Museum of Natural History. The 7-month heating season

from October to April results in an average annual building RH of 35% with the RH dropping below 40% for 60% of

the year. A humid building environment was simulated by inverting the Field Museum data to create an average

annual building RH of 55%. A moderate building environment was represented by a sine wave with an average RH

of 45% and an amplitude of 15%.

The three variables analyzed with the model were the case leakage rate, amount of gel inside the case, and the type of

gel. For Art-Sorb, simulations were run using both the company’s adsorption isotherm data and the isotherm

determined from the current study’s experiments. Table 4 lists the parameters and values that were used in the

simulations.

Case model simulation parameters and values.

Simulation Parameter Values Used in Simulations

file:///C|/Documents%20and%20Settings/Owner/My%20Documents/websites/museumClimateControls/SGelCases.htm (13 of 18)12/11/2007 11:43:48 AM

An Evaluation of Silica Gel for Humidity Control in Display Cases

Gel Sizing Factor (kg/m) 5, 10, 15, 20, 30, 50

Case Leakage Rate (ACD) 0.25, 0.5, 1, 2,5

Case RH set point 45%

Initial Gel RH Building

Environment

45%

dry, humid, moderate

Simulation Results

Figures 9-11 compare the simulation results for the dry, humid, and moderate building RH environments,

respectively. The Y-axis on each plot is the maximum predicted RH fluctuation inside a case over a one-year

simulation. The X-axis is the amount of gel inside the case per unit of case volume in the units of kg/m3. The

different lines on each graph represent the performance of the gel at a specific case leakage rate value, N, in units of

air changes per day. For example, looking at the Artengel plot in Fig. 9, a case with a leakage rate of 2 ACD (n=2)

and containing 20 kg/m3 of gel would undergo an RH fluctuation of 8% from the desired set point of 45% over an

entire year in a dry building environment.

For all three building environments, Artengel has the best performance yielding smaller case RH fluctuations than

the other two gels for a given case leakage rate and gel sizing factor. Since it has a constant M-value over the 30-

60% RH range, Artengel’s performance is not affected by different building environments. Since its M-value

increases with RH, Art-Sorb performs better in a humid building than a dry one. In contrast, regular density silica gel

performs better in a dry building than a humid one because its M-value is highest in the lower RH range.

There is little difference in the predicted performance of Art-Sorb using either the company or current study’s

isotherm data. The amount of gel required to keep the RH fluctuation to an acceptable level increases as the case

leakage rate increases. If the maximum desired case RH fluctuation over a one-year period is 10%, then a case

leakage rate of 2 ACD or less is necessary. Higher case leakage rates would require more than 30 kg/m3 of gel which

would likely be impractical and costly. Within the case leakage range of 0.25-2 ACD, between 5-30 kg/m3 of silica

gel would be required for adequate control over a one-year period.

Figure 9.Maximum predicted case RH fluctuations over one-year simulation for three silica gels in a dry

buildingenvironment for different case leakage rates (N) and gel sizing factors

file:///C|/Documents%20and%20Settings/Owner/My%20Documents/websites/museumClimateControls/SGelCases.htm (14 of 18)12/11/2007 11:43:48 AM

An Evaluation of Silica Gel for Humidity Control in Display Cases

Figure 10.As above, for humid buildingenvironment

file:///C|/Documents%20and%20Settings/Owner/My%20Documents/websites/museumClimateControls/SGelCases.htm (15 of 18)12/11/2007 11:43:48 AM

An Evaluation of Silica Gel for Humidity Control in Display Cases

Figure 11.As above, for moderate buildingenvironment

file:///C|/Documents%20and%20Settings/Owner/My%20Documents/websites/museumClimateControls/SGelCases.htm (16 of 18)12/11/2007 11:43:48 AM

An Evaluation of Silica Gel for Humidity Control in Display Cases

Conclusions

Based upon the experimental and computer simulation results of this study, the following conclusions can be made:

m All three gels would provide effective RH control using Thomson’s recommendation of 20 kg/m3 if the case

leakage rate is 1 ACD or less.

m On a pound for pound basis, Artengel has a higher buffering capacity than either regular density silica gel or

Art-Sorb.

m On a cost basis, regular density silica gel and Artengel have about the same cost for a given amount of

buffering capacity while Art-Sorb has twice the cost.

m Over the RH range of 30-60%, Artengel has a consistent performance, while Art-Sorb performs better above

50% and regular density silica gel performs better below 40%.

m For the conditions investigated, a case with a leakage rate of greater than 2 ACD would require more than 30

kg/m3 of gel in order to keep the display case RH fluctuation at 10% or below over a one year period.

m For the conditions investigated, a case with a leakage rate of 2 ACD or less would require 5-30 kg/m3 of gel

to keep display case RH fluctuations to 10% or less over a one year period.

References

ASHRAE, Applications Handbook, American Society of Heating, Refrigerating, and Air Conditioning Engineers,

Atlanta, GA (1999).

Ault, J., S.A. Klein, D.T. Reindl, J. Guay, “Indoor Environmental Control: Review of Current Recommendations and

Survey of Conditions at the Chicago Field Museum,” accepted for ASHRAE Transactions, March, 2001.

CCI (1984). Technical Bulletin 10: Silica Gel. CCI. Ottawa, Canada.

Dubinin, M., “Physical Adsorption of Gases and Vapors in Micropores,” Prog. Surf. Membrane Science, 9, pp. 1-70,

(1975).

Erhardt, D. and Mecklenburg, M., “Relative Humidity Re-examined,” Preventive Conservation: Practice, Theory and

Research, ed. by A. Roy and P. Smith. London, IIC, pp. 32-38, (1994).

Greenspan, L., “Humidity Fixed Points of Binary Saturated Aqueous Solutions,” Journal of Research of the National

Bureau of Standards – A. Physics and Chemistry, Vol. 81A, No. 1, Jan-Feb, (1977).

Guinchen, G., and Gai, V., “Controle du climate autour de 197 instruments de musique,” 7th Triennial Meeting,

ICOM Committee for Conservation, Copenhagen, 84.17.19-84.17.25, (1984).

Kafui, K.D., “Transient Heat and Moisture Transfer in Thin Silica Gel Beds,” Transactions of the ASME, Vol. 116,

pp. 946-953, Nov., (1994).

Polanyi, M., “Theory of Adsorption of Gases. A General Survey and some Additional Remarks,” Trans. Far. Soc.,

Vol. 28, 316-333, (1932).

file:///C|/Documents%20and%20Settings/Owner/My%20Documents/websites/museumClimateControls/SGelCases.htm (17 of 18)12/11/2007 11:43:48 AM

An Evaluation of Silica Gel for Humidity Control in Display Cases

Schweizer, F., “Stabilization of RH in Exhibition Cases: An Experimental Approach,” 7th Triennial Meeting, ICOM

Committee for Conservation, Copenhagen, 84.17.50-84.17.53, (1984).

Stolow, Nathan, “The Microclimate: A Localized Solution,” Museum News, Vol. 56(2): pp. 52-63, (1977).

Thomson, G., “Stabilization of RH in Exhibition Cases: Hygrometric Half-time,” Studies in Conservation, Vol. 22,

pp. 85-102, (1977).

[Search all CoOL documents]

[Feedback]

This page last changed: September 09, 2003

file://